Loading... Please wait...

Loading... Please wait...- Home

- Testing & Tools

- Tools

- Brazing & Soldering Tools

- Nitrogen Purging

- Uniweld 40040 Sludge Sucker Nitrogen Blaster Kit

Categories

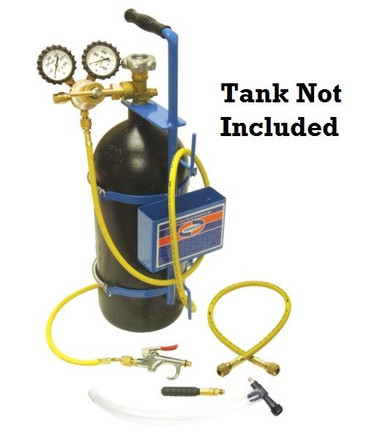

Uniweld 40040 Sludge Sucker Nitrogen Blaster Kit

Product Description

At one time it was acceptable to use refrigerant to clean out a condensate drain line, flush a system or blow off a condenser coil. In June of 1992, the venting of refrigerant was banned and the service tradesman was forced to look for new alternatives.

The Sludge Sucker Kit was born! Since its inception, the kits have been expanded for use with either Nitrogen or CO2. Why Nitrogen versus CO2. The preferred gas is Nitrogen because it's a dry inert gas that has multiple uses: purging a A/C&R system, leak testing a refrigerant line, calibrating pressure controls, cleaning a condensate drain line, cleaning coils, inflating tires, unclogging a sink, operating impact tools and much more. We do not recommend that CO2 be used for purging or pressure testing a A/C&R system because it may form carbonic acid within the system, causing premature equipment failure. There are certain applications where CO2 has its advantages. Because CO2 starts out as a liquid, it has a tremendous expansion rate; it is an ideal source for portable gas pressure. For example, a small 10 lb. cylinder of CO2 will yield approximately 90 cu. ft. of gas versus the same size cylinder of Nitrogen that will yield approximately 40 cu. ft. of gas. This makes CO2 ideal for clearing a condensate drain line, cleaning coils, inflating tires, unclogging a sink, operating impact tools and much more. The Sludge Sucker Kit options include a choice of high or low-pressure regulators for Nitrogen or CO2 and various carrying stands depending on tank size. (Tank not included)