Loading... Please wait...

Loading... Please wait...Categories

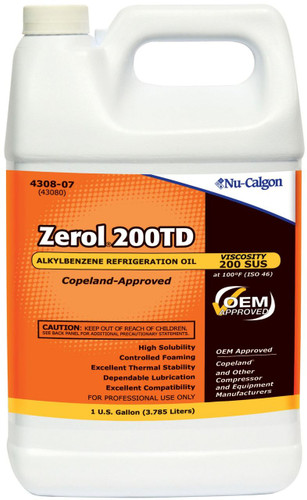

Nu Calgon 4308-07 Zerol 200TD Alkylbenzene Refriger Oil 1 GL

Product Description

Nu Calgon 4308-07 Zerol 200TD Alkylbenzene Refrigeration Oil 1 Gal

• Excellent miscibility & compatibility with all CFC & HCFC refrigerants

• Recommended by OEM’s for use with HCFC-based service blends

• Copeland approved (Zerol 200TD)

• Oil of choice for retrofitting with R401a, R401b, R402a, R402b and R123.

• Excellent “clean-up” and replacement oil in burn-outs.

Description

Zerol Refrigeration Oil is a high-quality, premium synthetic alkylbenzene refrigeration oil. It is similar in many ways to natural mineral oils but has superior properties that make it particularly valuable in refrigeration, air-conditioning applications. It is available in three grades: Zerol 150 (150 SUS), Zerol 200TD (200 SUS) and Zerol 300 (300 SUS). Zerol 200TD is a unique formulation of the alkylbenzene in that it contains a special additive package. This package includes an extreme pressure or EP lubricity additive as well as an additive that provides controlled foaming in specific operating conditions. It is preferred by Copeland for field service applications with the HCFC-based service

blends.

Features

Zerol Refrigeration Oil is recommended for use with all CFC and HCFC refrigerants as well as with hydrocarbons and ammonia in all refrigeration and air conditioning applications. It has the following distinct features:

• Solvency

• High Miscibility

• Low foaming

• Excellent Thermal Stability

• Low Floc Point Quality

• Excellent Compatibility

Solvency.

As a synthetic alkylbenzene, Zerol has excellent solvency. and because of this solvency, it has the ability to emulsify and clean up mineral oil deposits as well as carbonized oil stemming from a moderate burn-out. As a result, Zerol is an excellent lubricant to use as the first or initial flush oil in HFC-retrofits (see Zerol flush) as well as the flush and replacement oil in burn-outs where naphthenic mineral oils were used. Such burn-outs result in a considerable amount of acid by-products and

carbonized or burnt oil, and Zerol emulsifies this matter, enhancing the clean-up.

High Miscibility.

The primary reason for improved CFC and HCFC system performance with Zerol is its excellent

miscibility with fluorinated refrigerants like R-22 and R-502. Miscibility can be described as the ability of the refrigerant and lubricant to stay together as one homogeneous solution. Zerol has excellent miscibility with these refrigerants; the result is that the oil and the refrigerant will remain as one mixture at wide ranges in temperature and pressure. This is particularly true between Zerol and R-22, explaining why Zerol is the recommended lubricant for retrofitting with the HCFC service blends as they contain a significant amount of R-22.

Low Foaming.

The low-foam quality of Zerol, due to its high purity, helps eliminate explosive carry over at start-up, a potentially damaging situation caused by foaming and the subsequent oil loss from the crankcase. In the laboratory, Zerol has given outstanding performance vs. competitive oils in compressor foam-out tests. Practical application demonstrates this same low foaming tendency. In certain specific applications or where it is recommended by the equipment manufacturer, enhanced or controlled

foaming can be achieved through the use of Zerol 200TD.

Excellent Thermal Stability.

Zerol enhances the life of refrigeration systems by providing better thermal stability in the presence of refrigerants. Laboratory tests and field experience show that Zerol resists change under high temperatures, thus eliminating problems with sludge, acids, and copper plating. A good indicator of a lubricant’s stability is the sealed tube or Elsey test.

Low Floc Quality.

Because it is synthetic and is highly pure, it contains no paraffin or wax, a substance in mineral

oil that normally causes floccing or the formation of waxy deposits that can plug up a system. Strict quality controls from manufacturing through shipping ensure that Zerol maintains its high purity, allowing better efficiency at low temperatures, well below -100ºF.

Excellent Compatibility.

Converting refrigeration and air conditioning systems to Zerol is easily achieved due to its excellent compatibility. Zerol can be blended with conventional oils, is inert toward motor insulation, has UL

approval for use in hermetic systems, and is compatible with most elastomers and additives often used to improve lubricity such as tricresyl phosphate (TCP).

Applications

Because of its unique solvency and miscibility properties, Zerol is particularly useful in several specific applications. In burnouts, the solvency of Zerol enables it to be used to clean up the by-products and burnt oil while its exceptional miscibility with R-22 and R-502 makes it the oil of choice

with these two refrigerants, especially R-22 low temp applications. And this exceptional miscibility with R-22 is also why Zerol is recommended for use in retrofitting with the HCFC service blends as they are based on R-22.

Recommended for Burn-outs

In systems utilizing mineral oils where a moderate burn-out has occurred, Zerol can be used to flush and clean up the system. Zerol will emulsify the acid by-products, burnt oil and wax that result from such burn-outs, and allow the system to be flushed clean.